Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

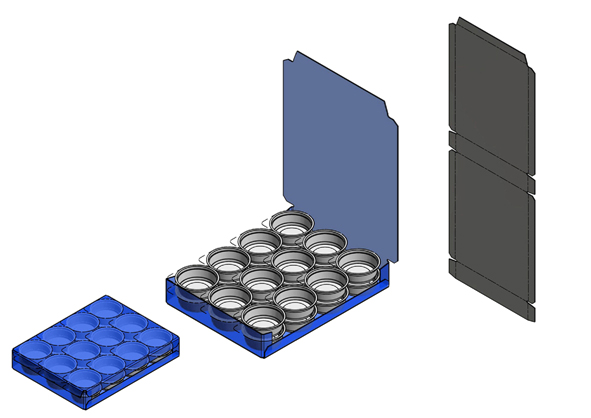

Podstawową funkcją urządzenia jest, składanie kartonów z płaskiego wykroju, układanie opakowań jednostkowych (kubki, kostki masła, saszetki, butelki) w z złożonym kartonie oraz sklejanie kartonu przy pomocy gorącego kleju HOT MELT.

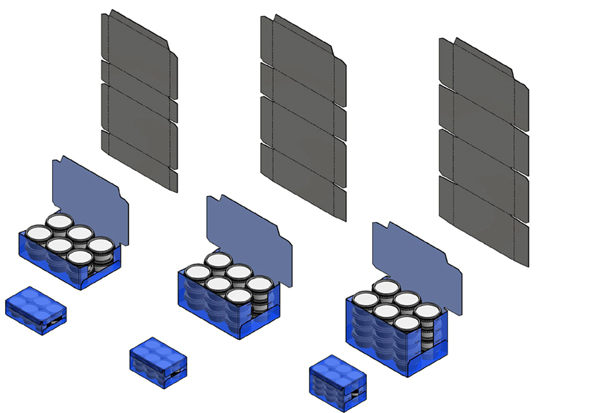

Proces pakowania podzielony jest na cztery etapy:

Kartoniarka Wrap Around charakteryzuje się rozwiązaniami, których zadaniem jest optymalizacja procesu pakowania:

| Parametry techniczne | KWA 3 x 2 |

| Oczekiwana wydajność opakowań jednostkowych | 10 000 opakowań jednostkowych na godzinę |

| Wydajność pakowania | Do 27 kartonów/min |

|

Konfiguracja opakowań jednostkowych w kartonie zbiorczym Ilość poziomów |

1, 2, 3, 4 |

| Sprężone powietrze: Ciśnienie robocze powietrza Zgodne z normą z ISO 8573-1 |

min 0,7 MPa |

| Rozmiary | Zależne od systemu grupowania opakowań |

| Moc zainstalowana | ~ 5,5 KW |

| Zasilanie | 400 V/50 Hz |

| Wykonanie | Stal nierdzewna AISI 304 Aluminium anodowane Tworzywa sztuczne |

| Podzespoły elektryczne | Moeller, Schneider, Siemens, Omron, LG |

| Czujniki | BALLUFF, OMRON, TURCK |

| Pneumatyka | Festo/SMC/metalwork |

| Sterownik | Siemens |

| Serwa | Schneider |

| Panel sterowania domu: Ekran dotykowy z dużym, jasnym ekranem |

9,6" |

| Hot-Melt | Nordson |