Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

PAC 12.0 - 14 000 opak./h

PAC 9.0 - 8 800 opak./h

PAC 7.5 - 7 200 opak./h

PAC 5.0 - 4 800 opak./h

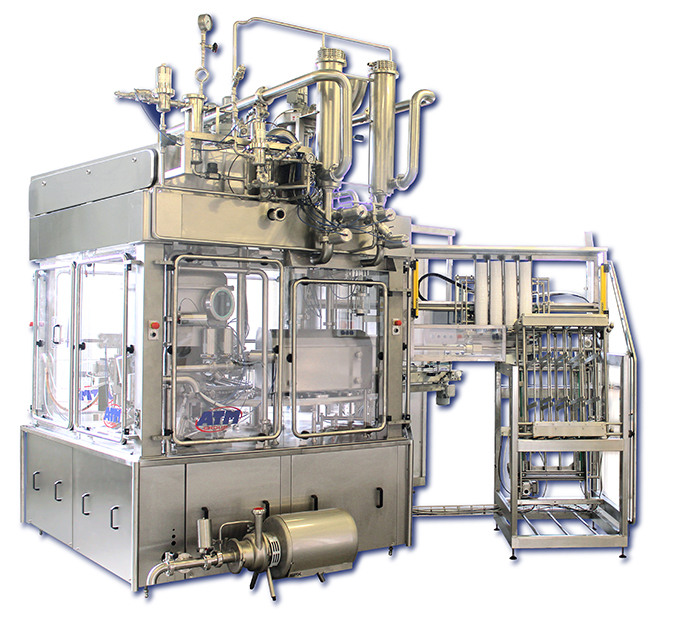

Pakowaczka rotacyjna przeznaczona jest do dozowania i pakowania produktów spożywczych w gotowe kubki z tworzywa sztucznego, zamykane platynką termozgrzewalną, oraz dodatkową przykrywką z tworzywa sztucznego.

Zastosowanie w przemyśle:

Konstrukcja maszyny zapewnia prosty i praktyczny sposób obsługi. Solidna konstrukcja , oraz użyte wysokiej jakości materiały do budowy urządzenia, zapewniają długoletnią pracę i odporność na warunki panujące w zakładach przetwórstwa spożywczego. Głównymi elementem wykonawczym pakowaczki rotacyjnej są podzespoły taktujące wykonujące ruch obrotowy stołu rotacyjnego:

Wokół stołu rotacyjnego, wyposażonego w kasety z gniazdami, umieszczone są poszczególne stacje robocze wykonawcze, takie jak:

Urządzenie wyposażone w sterowanie PLC który nadzoruje w pełni automatyczny proces pakowania

Dotykowy panel sterowania zapewnia prostą obsługę przez zastosowanie ikon graficznych

|

OPIS |

FUNKCJE |

STANDARD |

OPCJA |

|

WYDAJNOŚĆ Typ urządzenia: PAC 5.0 do 12.0 |

4800 do 14 000 Opakowań na godzinę |

|

|

|

RODZAJ URZĄDZENIA |

Rotacyjne |

|

|

|

ŚREDNICA OPAKOWANIA |

Ø 95 mm |

|

|

|

Ø 75 mm |

|

||

|

Pozostałe wymiary |

|

||

|

TYP DOZOWANEGO PRODUKTU Płynny |

Śmietanka, pasztet, sosy, |

|

|

|

Półpłynny |

Jogurt, śmietana, Kefir, majonez, farsz mięsny, dżem |

|

|

|

Pastowaty |

Serki homogenizowane , desery, powidła, sałatki |

|

|

|

MAKSYMALNA TEMPERATURA DOZOWANEGO PRODUKTU |

90°C |

|

|

|

UKŁAD STEROWANIA PLC |

SIEMENS |

|

|

|

UKŁAD NAPĘDOWY URZĄDZEŃ |

Mechaniczny |

|

|

|

SEKCJA PODAWANIA KUBKÓW W GNIAZDA KASET |

Mechaniczna/ pneumatyczna |

|

|

|

STERYLIZACJA KUBKA PRZED ZADOZOWANIEM |

Lampy UV |

|

|

|

STERYLIZACJA KUBKA PRZED ZADOZOWANIEM ( dotyczy PAC 9.0 ) |

H202 |

|

|

|

DOZOWNIKI : ZAKRES DOZY Przed dozownik |

5 do 50 ml |

|

|

|

Dozownik główny |

100 do 500 ml |

|

|

|

Za dozownik |

5 do 50 ml |

|

|

|

RODZAJ DOZOWNIKÓW |

Objętościowy |

|

|

|

Wagowy |

|

||

|

Kompensacyjny |

|||

|

PRZYSTOSOWANIE DOZOWNIKÓW DO MYCIA W CIP Przed dozownik |

Automatyczny |

|

|

|

Dozownik główny |

Automatyczny |

|

|

|

Za dozownik |

Automatyczny |

|

|

|

ZBIORNIKI PRODUKTU ZAMKNIĘTE Przed dozownik |

Pojemność 30 l |

|

|

|

Dozownik główny |

Pojemność 90 l |

|

|

|

Za dozownik |

Pojemność 30 l |

|

|

|

NADCIŚNIENIE STERYLNEGO POWIETRZA W ZBIORNIKACH PRODUKTU |

System kontroli nadciśnienia w zbiorniku |

|

|

|

POMPA ODBIORU CZYNNIKA MYJĄCEGO Z UKŁADU CIP PAKOWACZKI |

Wydajność pompy 20 000 m3/h |

|

|

|

STACJA PODAWANIA GOTOWYCH PLATYNEK TERMOZGRZEWALNYCH NA KUBKI |

Mechaniczna/ Pneumatyczna |

|

|

|

UKŁAD STERYLIZACJI PLATYNKI PRZED ZGRZANIEM |

Lampy UV/IR |

|

|

|

ZGRZEWARKA GŁÓWNA PLATYNKI Z KUBKIEM |

Pneumatyczna z kontrolą położenia |

|

|

|

SYSTEM KONTROLI ZGRZEWU |

optyczny |

|

|

|

STACJA PODAWANIA GOTOWYCH PRZYKRYWEK Z TWORZYWA SZTUCZNEGO |

Pneumatyczna z kontrolą położenia |

|

|

|

SYSTEM PRZEKAZYWANIA OPAKOWAŃ NA TRANSPORTER ODBIORCZY |

Pneumatyczny |

|

|

|

TRANSPORTER ODBIORCZY GOTOWYCH OPAKOWAŃ |

Taśmowy |

|

|

|

DATOWNIK INK JET |

Data nanoszona z boku lub z góry |

|

|

|

SYSTEM SŁUŻĄCY DO NANOSZENIA DATY NA DNIE OPAKOWANIA |

Transporter specialny |

|

|

|

WYSOKA ZABUDOWA MASZYNY PAKOWANIA |

Zamknięta kabina pakowania |

|

|

|

SYSTEM WYTWARZANIA STERYLNEGO POWIETRZA W KABINIE PAKOWANIA : ULTRA CLEAN |

Sterylne filtry HEPA z systemem wytwarzania nadciśnienia w kabinie |

|

|

|

MODEM TELEKOMUNIKACYJNY |

Ethernet |

|

|

|

AUTOMATYCZNY SYSTEM GRUPOWANIA GOTOWEGO PRODUKTU DO OPAKOWAŃ ZBIORCZYCH |

Serwo napęd |

|