Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

Napisz do nas

ul.Jankowicka 19

44-321 Marklowice

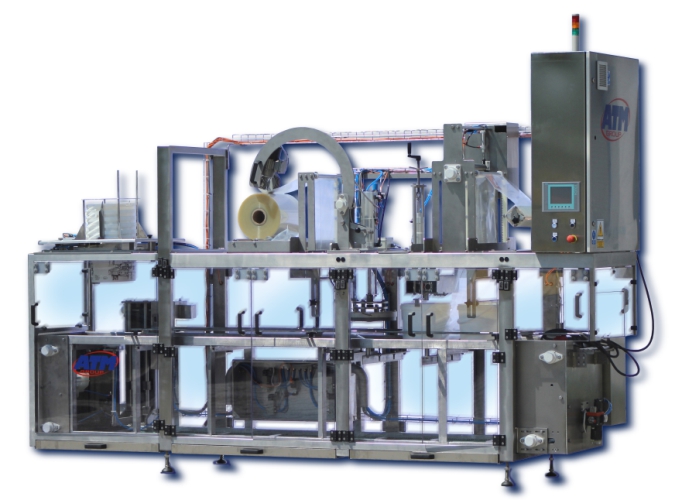

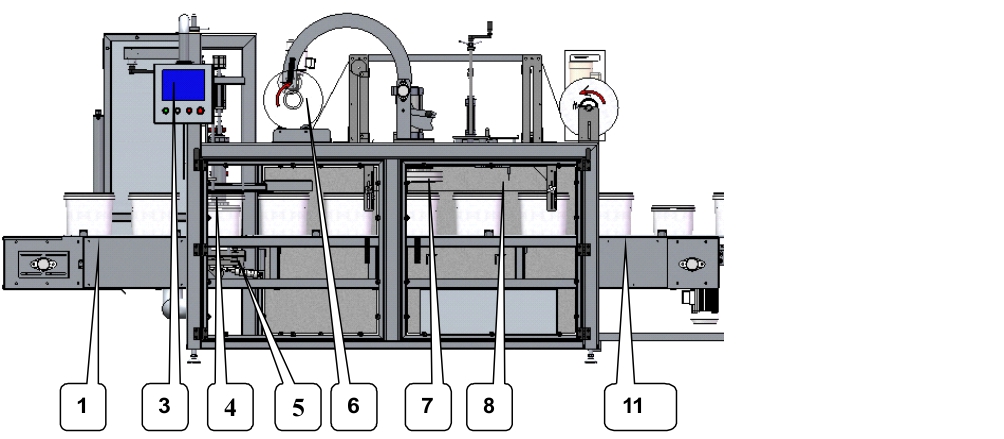

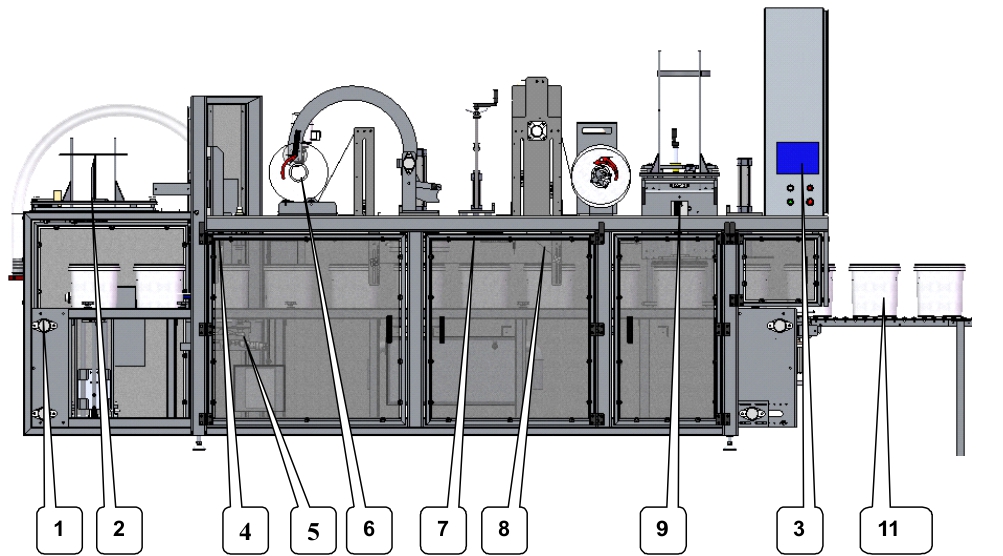

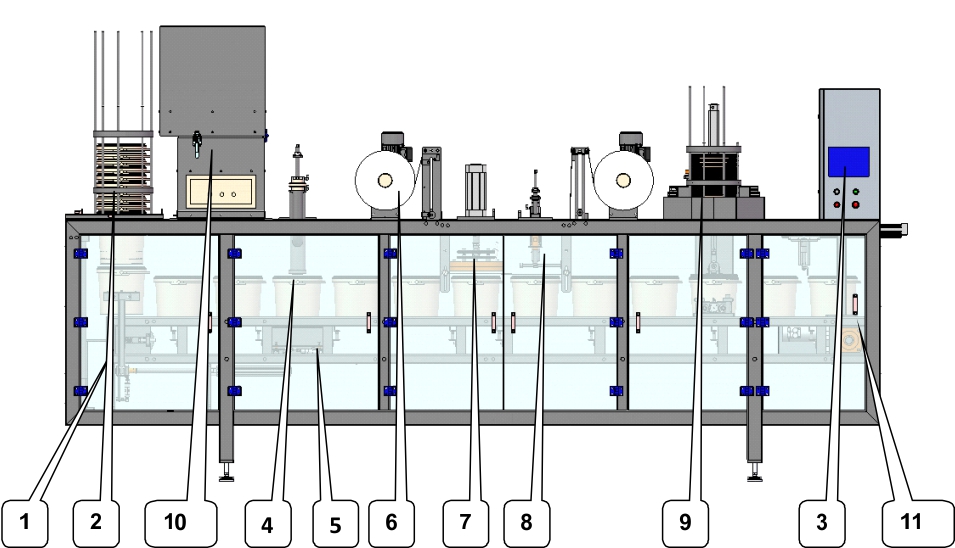

Urządzenia o konstrukcji liniowej, przeznaczone do dozowania produktów w wiaderka z tworzywa sztucznego o pojemnościach od 1 do 20 litrów. Wiaderka zgrzewane są folią, wycinaną z rolki i zamykane przykrywką z tworzywa sztucznego. Opakowania poruszają się ruchem "start-stop" za pośrednictwem transportera taktującego i mogą być transportowane w jednym lub dwóch rzędach, w zależności od wybranego modelu.

Wzdłuż transportera taktującego mogą być zainstalowane następujące stacje robocze:

OPIS: